Now that summer is upon us and night fishing is firing up, I wanted to revisit an article from a couple of years ago that is a step by step install of LED fishing lights. More specifically, these are SuperNova Fishing Lights. They have changed a bit in appearance since then but the principles are exactly the same.

Contributed by Michael Guyer

One of the biggest impediments to fishing at night is vision. In order to cast to structure and points, you have to be able to see them. However, traditional lighting methods tend to ruin your night vision and/or draw in too many insects. That’s where LED fishing lights come in. My favorite brand to use is SuperNova Fishing Lights. They offer LED strip lighting in various colors and lengths that you can apply to your kayak to solve your need for lighting, and at the same time make you more visible to other boaters. Here, I’ll detail the highlights of mounting SuperNova Fishing Lights LED strips.

For starters, I mocked up where I believed I needed/wanted the strips to be. I simply laid everything out and held them in place with painters tape. Among other things, this allows me to determine if the power leads need to be extended. I’m glad that I used tape, because in the end I did adjust the final installation location a bit.

I also decided that I would like some utility, or task, lighting in my tankwell and cockpit.

Next, I chose a location for my switches. These are waterproof, and I wanted them where they would be out of the way, yet accessible. While not shown, after choosing the location, I laid out a template on painters tape, marked the holes using a ruler to ensure proper spacing and alignment, and then drilled the holes.

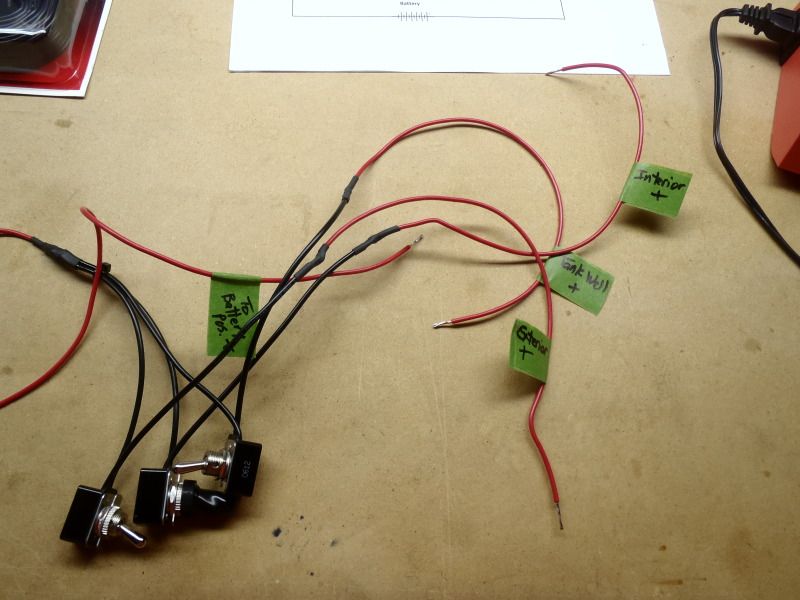

Every switch shares a common power, or “hot” lead, and I found it easiest to mark and assemble the switches on my workbench and then install them. Soldering the connections and using heat shrink tubing (supplied with the kit) ensures that the connections stay solid and waterproof.

The switches fit so tightly in the holes that I drilled, and are high enough up in the hull, that I didn’t feel it necessary to seal them with a product like LEXEL, but you always have the option to do so if you wish. Here they are installed.

With the exception of the switches, I didn’t want to make any part of the install permanent until everything was tested. In these photos, small holes have been drilled to run the wires inside the hull, but nothing is sealed or permanently attached. I conducted preliminary testing with all wiring outside the hull.

With everything tested and final placement determined I was able to make the final solder connections inside the hull. NOTE – Visible beneath the soon-to-be-soldered connection is the lead for one of the LED strips that went on the bow. As you can see, the holes drilled to allow running the wires inside the hull were no larger than absolutely necessary and you can also see some of the wire management clips..

While not pictured, the final steps in permanently mounting the lights are as follows –

1. Clean any areas where LED strips need to adhere with isopropyl alcohol and allow it to dry.

2. Apply adhesion promoter (supplied with the kit) to those areas where the two-sided tape that is already attached to the LED strips needs to stick on the hull.

3. Peel the protective covering off the tape and firmly press the LED strip in place. NOTE – Peel back just a few inches of the protective cover at a time, press the strip in place and continue to peel and press as you work your way along. It pays to take your time here, as once the tape sticks to your hull, it is nearly impossible to remove.

4. Finally, I put a dab of LEXEL on all the holes that went through the hull to keep things watertight and I allowed it to dry for 24 hours. I took this opportunity to go inside the hull and “dress” all the wiring with wire management and cable ties. This keeps them neat, protected and out of the way.

While the steps are not documented here, I built a watertight battery box to house a standard 12V/7ah battery. I attached a quick disconnect to the battery box and to my wiring so that I can simply unplug the harness and remove the battery box when it’s time to charge my battery. Inside the box is a 5A fuse to keep everything protected.

I knew that I would also be using the original SuperNova Fishing Lights submersible light to attract baitfish, so I wired in another connector that is identical to the one I used on the battery box to allow me to simply plug it in if I wanted to use the that light. Again, I chose a location that I could get to easily, but wouldn’t be in my way. I also installed a strain relief when I attached the connector to the light so that it wouldn’t go sailing off if I tossed it out with too much enthusiasm..

On the water with the finished product –

13 thoughts on “Installing LED Fishing Lights”

Comments are closed.

I was wondering what gage wire you used on te install

20 or 22 is fine.

That’s awesome! I can see some lights in my future!!!!!

What kind of battery do you recommend? Motorcycle, lawn mower battery? I just recieved my kit and cannot wait to get em’ installed and then out to the water.

I’ve had inquiries as to what battery I use. Normally, a 7aH battery like we use for a fish finder or deer feeder is more than enough. You could step up to a 12aH or so if you anticipate using a fish finder as well, or if you will be camping and not have the ability to recharge your battery for a week or so.

Thanks for the advice. How much running time will a 7aH battery give you with these lights?

Even with every light energized, to include the submersible, I’ve been able to run them for days. I’ve never run them so long that the battery died.

One more question and this will probably qualify as the “dumb question”. The boots on my switches have a lot of slack between them and the actual toggle underneath. Is this normal and were yours like that? The boots are not intended to be heat shrunk are they? I am thinking about getting some more.

That’s how they come. You don’t heat shrink them. It was important that the threaded portion was brass and not a ferrous metal. The trade-off is that the boot is a bit long. Some of us take it a step further and fill the boot with dielectric grease to keep it REALLY waterproof.

Are the boots on these switches intended to be shrunk with heat? They are twice as long as the toggles underneath.

I never would have guessed it. Thanks for the advice!!!

that looks nice